Industrial Monitoring Experts

We help companies to understand and control their production processes and industrial machinery from a single, centralised interface

Manufacturing monitoring to improve your plant production

360° Monitoring - Your production at a glance

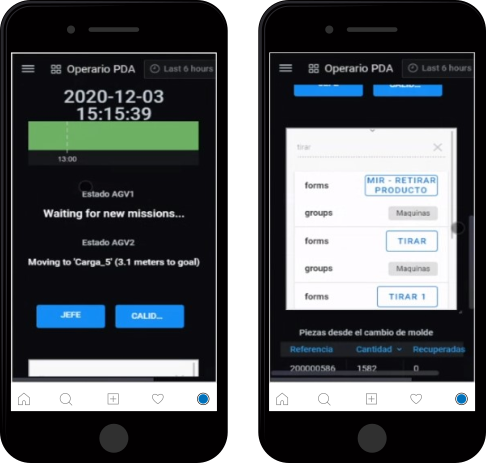

Access your production data from anywhere and on any device, in real time.

Muutech’s monitoring platform helps you make the right decisions, which will allow you to reduce and eliminate line and industrial machinery stoppages and inefficiencies.

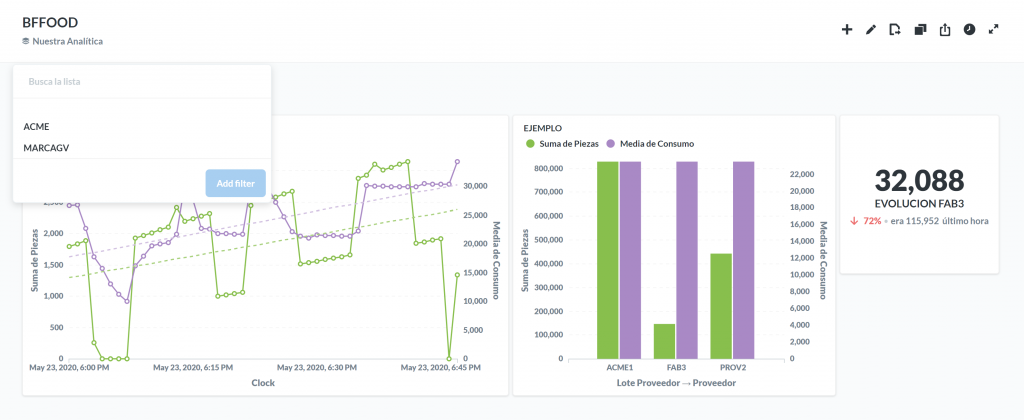

Through dynamic graphics and customized dashboards we help you to know at any time the status of your processes and machines. Prevent problems before they occur.

We integrate with your processes, machines and systems

Start collecting data from your production processes and machines within minutes, whether they are connected to the network or not, regardless of the manufacturer or location.

We collect and analyse data from:

– Wired or wireless industrial sensors

– Computers, PLCs, industrial automatons, robots, etc.

– Numerical control machines (CNC)

– Industrial communication networks (Profibus, Profinet, Ethernet, …)

– Servers and network equipment

– Databases

We integrate with existing production systems such as ERP, MES or SCADA.

Our customers already enjoy process monitoring

Industrial process monitoring in one company from the Automotive branch

Muutech's industrial process monitoring pilot project is carried out in collaboration with a supplier of high quality products in the automotive sector in the Vigo region (Spain). The objective is to provide a simple use and integration tool, which provides an overview of the status of various production processes, and helps the quality team react to drifts in the manufacturing area...

Control of production costs by monitoring electrical consumption

How much does it cost me to produce? Which of my products generates the most profit? Do my prices match my costs?

These and similar questions are asked by almost all production companies on a monthly basis, however, we would be surprised at the multitude of companies that...

Minerva is our real-time industrial monitoring platform

Supervises

Supervises, controls and manages all equipment, production devices and industrial machinery.

Visualizes

Collects information from any information source and displays it on customized dashboards.

Informs

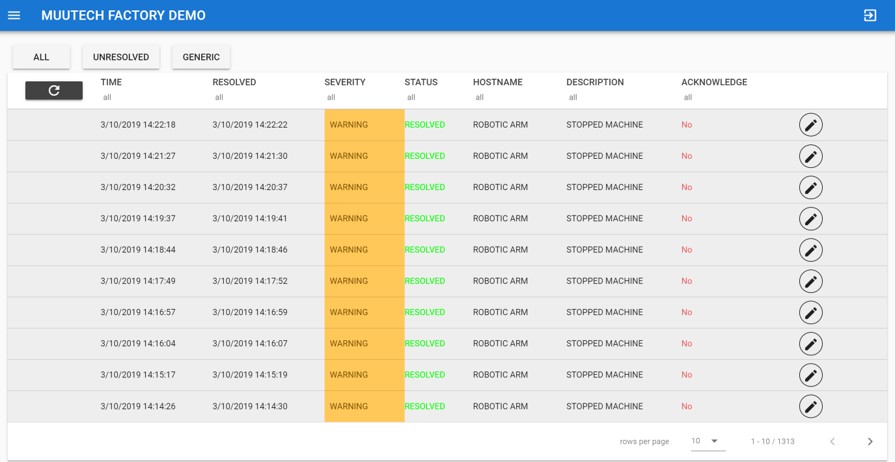

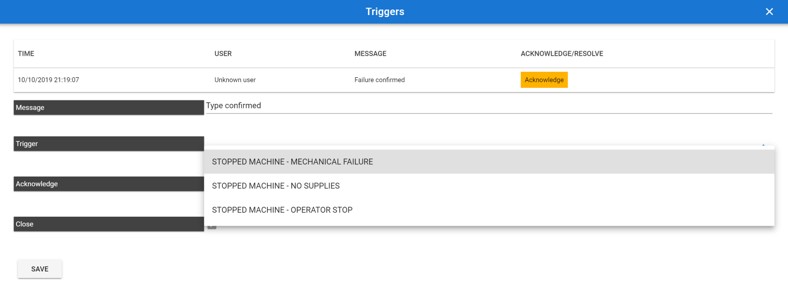

Alarms designed to your needs, with the only purpose of predicting incidents before they occur, and to correct them

Full visibility, automatic collection from any source

Data analysis and process optimization

Analysis based on real information:

Breakdown and failure analysis - predictive maintenance

The operator has a record of the incidents and gives him the possibility to include the information he needs. In addition, operators can add context and additional data thanks to the inclusion of customized forms, by department.

Notifications and alerts

Industrial BI - "PowerBI" for real-time industrial data

Advanced visualization